- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: wide neck preform hand feeding bottle blow molding system 2 cavity

Key words: bottle blow molding system, bottle blowing machine, bottle blow molding machine

Model: CP-2B

Brand: FILL-PACK

Power: 18kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: pneumatic

Automation degree: Semi Automatic

Application: bottle blowing

Processing steps: preform heating- blowing

Condition: New

PROPERTIES:

Capacity: 2000-2400BPH

Key material: cast iron

Fuction: PET bottle producing

Processing material: PET

Bottle volume: 0-2000ml

Cooling way: water chilling

Preform Heating temprature: 0-200 ℃

Preform feeding way: manual

Blowing pressure: 30kg

Air consumption: 2.4m3/min 3MPA

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

1. The bottle blow molding system adopts human`computer interface to control the whole working procedures, auto`loading, auto blowing, auto dropping. Action cylinders are all assembled with magnetic induction switches.Connect with PLC to control every step and test every cylinder. Next action will continue after the former step done, If former step is not finished, alarm automatically and do not work. PLC displays problem position.

2. Fast speed, accurate position, smooth action.

3. According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustableaccording to the bottle size to save the time.

4. Far infrared heater lamps have strong penetrations , preforms are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group of temperature separately.

5. The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

6. Special recycling installation for high pressure air reduce the energy consumption.

8. Operation consists of manual and automatic precedure, manual operation for assembly and test, automatic operation for production.

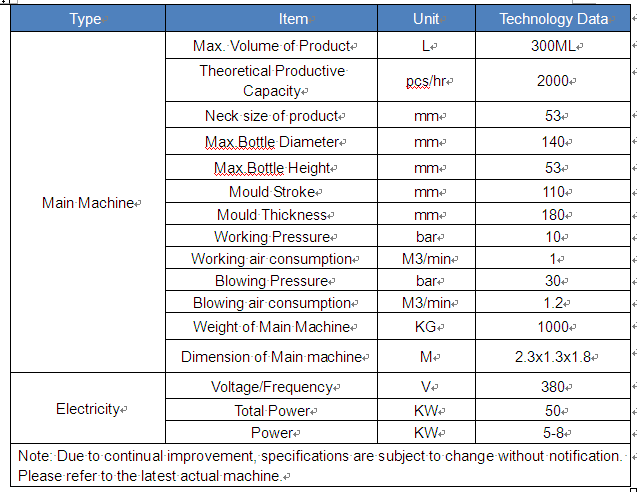

Parameters of bottle blow molding system

1, Sea shipping worthy packing for bottle blow molding system

2, Moulds with rust-proof treatment

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: